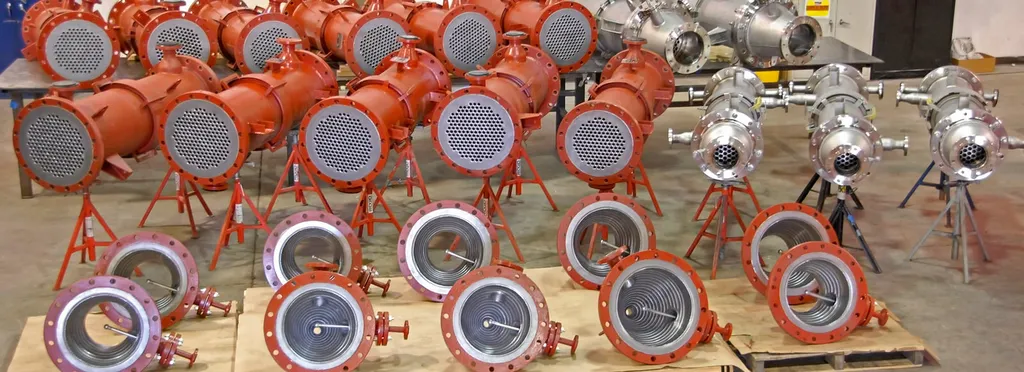

Kaltra stands as an international powerhouse, crafting energy-efficient chillers, free cooling systems, precision air conditioners, and microchannel heat exchangers for the demanding environments of data centers and various industries. With its roots firmly planted in Munich, this global player extends its reach to over 60 countries, demonstrating a commitment to environmental friendliness and unwavering reliability. But even the most robust systems, like Kaltra’s kkt chillers, require consistent care to maintain peak performance. So, how do you unlock the full potential of your KKT chiller? Let’s dive into essential maintenance practices.

Understanding the Importance of Regular KKT Chiller Maintenance

Why is consistent kkt chiller maintenance so crucial? Imagine a high-performance sports car. Without regular oil changes, tire rotations, and tune-ups, its performance would quickly decline, and costly repairs would become inevitable. Similarly, neglecting your KKT chiller can lead to reduced efficiency, increased energy consumption, and unexpected downtime, all impacting your bottom line.

Think of it this way. A well-maintained chiller operates smoothly, consistently delivering the cooling capacity you need. This directly translates to lower energy bills and a longer lifespan for your equipment. Moreover, proactive maintenance helps identify and address minor issues before they escalate into major, expensive problems. This not only saves money but also prevents disruptions to your critical operations.

Key Areas of KKT Chiller Maintenance

To keep your KKT chiller operating at its best, focus on these key areas,

Condenser Coil Cleaning

The condenser coil is responsible for rejecting heat from the refrigerant. Over time, dust, dirt, and debris can accumulate on the coil surface, reducing its ability to transfer heat effectively. This leads to higher operating pressures and reduced cooling capacity. Regularly cleaning the condenser coil with a soft brush or pressure washer (following manufacturer guidelines) is essential. How often should you clean it? This depends on the environment, but generally, monthly inspections and cleaning as needed are a good starting point.

Refrigerant Level Monitoring

Refrigerant is the lifeblood of your chiller. Low refrigerant levels can significantly reduce cooling capacity and increase energy consumption. Regular monitoring of refrigerant levels is crucial. If you notice a drop in refrigerant, consult a qualified technician to identify and repair any leaks before adding more refrigerant. Remember, proper handling of refrigerants is important for environmental protection.

Water Treatment and Monitoring

For water-cooled chillers, maintaining proper water treatment is paramount. Scale, corrosion, and biological growth can all negatively impact heat transfer efficiency and damage chiller components. Implement a comprehensive water treatment program that includes regular water testing, chemical treatments, and cleaning of cooling towers and water circuits. Are you testing your water regularly? This simple act can extend the life of your chiller.

Electrical Connection Inspections

Loose or corroded electrical connections can lead to voltage drops, overheating, and equipment failure. Regularly inspect all electrical connections, tightening any loose connections and cleaning any corrosion. This not only improves chiller performance but also enhances safety.

Filter Maintenance and Replacement

Air filters protect the chiller’s internal components from dust and debris. Clogged filters restrict airflow, reducing cooling capacity and increasing energy consumption. Regularly inspect and replace air filters according to the manufacturer’s recommendations. A clean filter translates to a happy and efficient chiller.

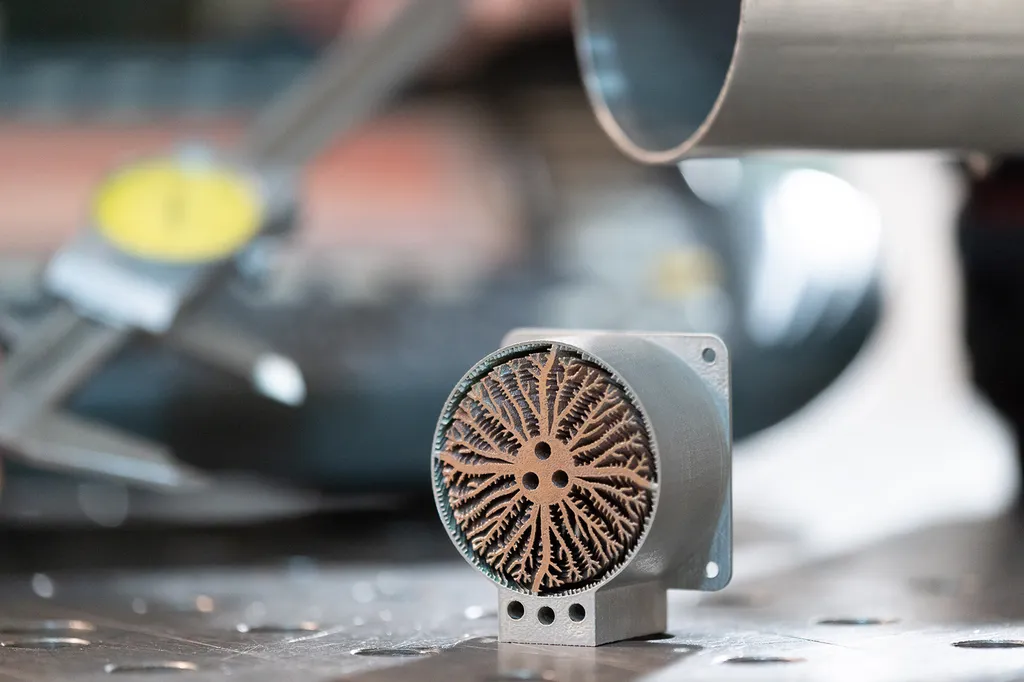

Oil Analysis

In lubricated chillers, oil analysis provides valuable insights into the condition of the compressor and other moving parts. Regular oil samples can identify contaminants, wear particles, and other signs of potential problems. Analyzing these samples allows for proactive maintenance and prevents costly repairs.

Benefits of Consistent KKT Chiller Maintenance

The benefits of embracing consistent KKT chiller maintenance extend far beyond simply keeping your equipment running. It’s about optimizing performance, minimizing downtime, and protecting your investment.

- Increased Efficiency, A well-maintained chiller operates at peak efficiency, reducing energy consumption and lowering operating costs.

- Extended Lifespan, Regular maintenance helps prevent premature wear and tear, extending the lifespan of your chiller and maximizing your return on investment.

- Reduced Downtime, Proactive maintenance helps identify and address potential problems before they lead to unexpected downtime, ensuring uninterrupted cooling for your critical operations.

- Improved Reliability, A well-maintained chiller is a reliable chiller, providing consistent and dependable cooling performance.

- Lower Repair Costs, Addressing minor issues early on prevents them from escalating into major, expensive repairs.

By prioritizing regular KKT chiller maintenance, you’re not just keeping your equipment running; you’re investing in its long-term health, efficiency, and reliability. And that’s a smart move for any business.