Kaltra, as an international company, plays a pivotal role in shaping how we cool our increasingly demanding data centers and industrial facilities. Operating from its base in Munich and extending its reach to over 60 countries, Kaltra is known for manufacturing energy-efficient chillers, free cooling systems, precision air conditioners, and microchannel heat exchangers. But what makes these components truly stand out, and how can they contribute to more sustainable cooling strategies? Let’s delve into the details.

Understanding Kaltra’s Cooling Solutions

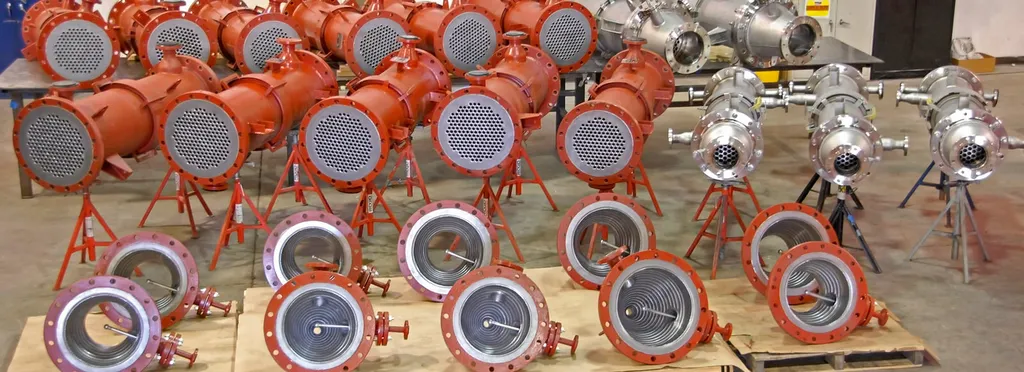

Kaltra doesn’t just manufacture equipment, it crafts solutions. Their chillers, for example, are engineered for optimal energy performance, reducing the overall power consumption of cooling operations. This is vital, especially considering the massive energy demands of data centers.

Free cooling systems represent another area of Kaltra’s expertise. These systems leverage ambient temperatures, particularly during cooler months, to reduce the reliance on mechanical cooling. What if we could simply use the environment to our advantage? That’s precisely what free cooling aims to achieve.

Precision air conditioners are critical for maintaining the stable environmental conditions required by sensitive electronic equipment. Fluctuations in temperature and humidity can spell disaster for data centers. Kaltra’s precision air conditioners offer the reliability needed to prevent such scenarios.

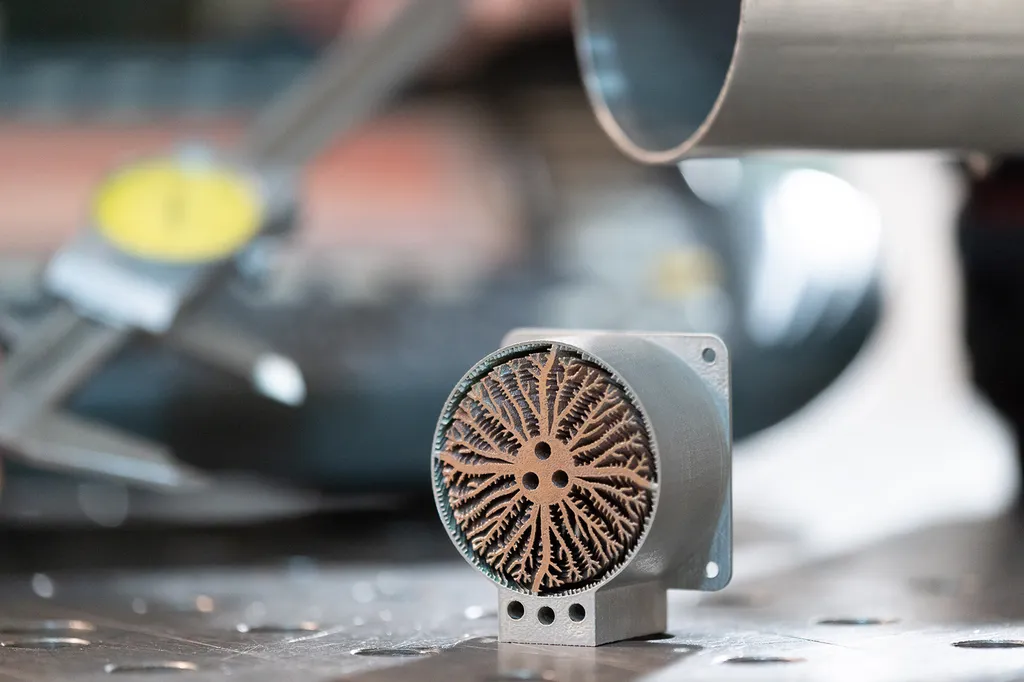

Finally, microchannel heat exchangers are used in a variety of applications, including chillers and air conditioners. Their compact design and enhanced heat transfer capabilities contribute to the overall efficiency of Kaltra’s cooling systems.

The Significance of Environmental Friendliness and Reliability

In today’s world, environmental responsibility isn’t just a buzzword, it’s a necessity. Kaltra understands this, placing a strong emphasis on environmental friendliness in its product design and manufacturing processes. By producing energy-efficient equipment, Kaltra helps its customers reduce their carbon footprint and comply with increasingly stringent environmental regulations.

Of course, environmental friendliness would be meaningless without reliability. Downtime in a data center or industrial facility can have severe financial and operational consequences. Kaltra’s commitment to reliability ensures that its cooling systems operate consistently and predictably, minimizing the risk of disruptions.

The Role of Pre-Cooling in Energy Efficiency

One particularly effective method for boosting energy efficiency is pre-cooling. The idea behind pre-cooling is simple, yet powerful − by cooling air or water before it enters the primary cooling system, you reduce the workload on that system and, consequently, its energy consumption. This can be achieved in several ways, including using evaporative coolers or ground-source heat exchangers.

Imagine a hot summer day. Instead of directly feeding hot outside air into your chiller, you first run it through an evaporative cooler, dropping its temperature significantly. The chiller now has to work much less to achieve the desired cooling effect. This is the essence of pre-cooling.

The use of pre-cooling can significantly reduce energy consumption, extend the lifespan of cooling equipment, and lower operating costs. For businesses aiming to shrink their environmental impact and save money, pre-cooling is a valuable consideration.

Applying Kaltra’s Solutions in Practice

How does all of this translate into real-world applications? Consider a large data center in a hot climate. By integrating Kaltra’s energy-efficient chillers with a free cooling system and a pre-cooling setup, the data center can drastically cut its energy consumption during the cooler months and shoulder the load during hot times.

Similarly, an industrial facility that relies on precise temperature control for its manufacturing processes can benefit from Kaltra’s precision air conditioners and microchannel heat exchangers. By optimizing the cooling system for both efficiency and reliability, the facility can maintain consistent production levels and minimize downtime.

Conclusion − Investing in a Sustainable Future

Kaltra’s commitment to energy-efficient cooling solutions, environmental friendliness, and reliability makes it a valuable partner for businesses seeking to optimize their cooling operations. Whether it’s through innovative chillers, free cooling systems, precision air conditioners, or microchannel heat exchangers, Kaltra is helping to shape a more sustainable future for data centers and industry. By embracing solutions like pre-cooling, businesses can not only reduce their environmental impact but also unlock significant cost savings. Isn’t it time to consider how Kaltra’s technologies can benefit your operations?