Kaltra, an international company based in Munich, designs and builds energy-efficient cooling solutions. With operations spanning over 60 countries, the company is a significant player in the data center and industrial cooling sectors. Kaltra’s commitment to environmental friendliness and reliability shines through in its range of products, which include chillers, free cooling systems, precision air conditioners, and microchannel heat exchangers. But what about the individual components that make these systems so effective? Let’s examine one crucial element; the ammonia heat exchanger.

Understanding the Role of Heat Exchangers in Cooling Systems

Heat exchangers are fundamental components in many cooling systems. They facilitate the transfer of thermal energy between two or more fluids, enabling the removal of heat from one medium and its dissipation into another. This process is central to refrigeration, air conditioning, and many industrial processes. How do they work, and why are they so important?

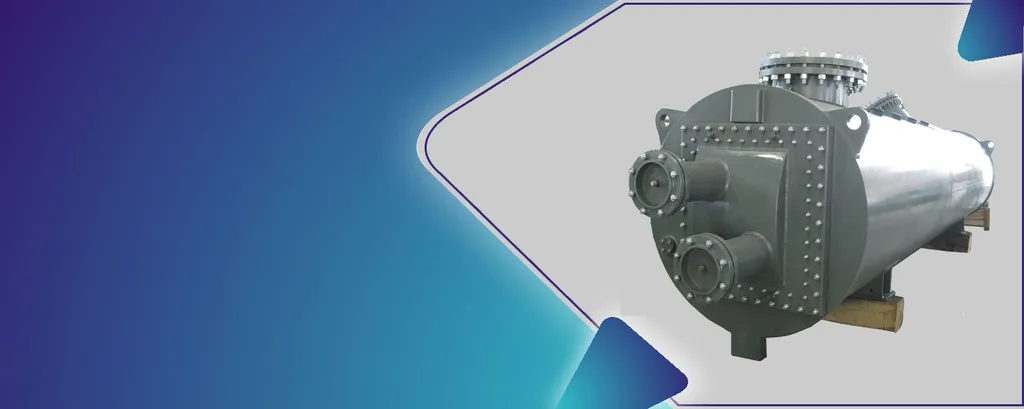

Essentially, a heat exchanger provides a pathway for heat to move without allowing the fluids to mix. This is achieved through various designs, such as plate, shell-and-tube, and microchannel configurations. The choice of design depends on factors like the application, the fluids involved, and the desired efficiency.

Ammonia as a Refrigerant and the Rise of the Ammonia Heat Exchanger

While various refrigerants are available, ammonia stands out for its excellent thermodynamic properties and environmental advantages. Ammonia (NH3) has a high latent heat of vaporization, meaning it can absorb a significant amount of heat as it changes from liquid to gas. This characteristic makes it an incredibly efficient refrigerant.

Furthermore, ammonia has a zero ozone depletion potential (ODP) and a negligible global warming potential (GWP), making it a far more sustainable choice than many synthetic refrigerants. This is where the ammonia heat exchanger comes into play. These specialized exchangers are designed to handle ammonia safely and efficiently, maximizing its potential as a cooling agent.

But, why aren’t ammonia heat exchangers more ubiquitous? One reason is the toxicity of ammonia. Precautions must be taken to prevent leaks and ensure safe operation. Another factor is the material compatibility requirements. Ammonia can corrode certain metals, so heat exchangers designed for ammonia must be constructed from appropriate materials, such as stainless steel or aluminum.

Benefits of Utilizing Ammonia Heat Exchangers

The advantages of integrating ammonia heat exchangers into cooling systems are numerous. First and foremost, these exchangers contribute to enhanced energy efficiency. By leveraging ammonia’s superior thermodynamic properties, systems can achieve higher cooling capacities with lower energy consumption. This translates to reduced operating costs and a smaller carbon footprint.

Second, the environmental benefits are substantial. The switch to ammonia-based systems helps reduce reliance on refrigerants with high GWP, contributing to global efforts to mitigate climate change. For businesses committed to sustainability, adopting ammonia heat exchangers is a tangible way to demonstrate their environmental responsibility.

Third, modern designs of heat exchangers address safety concerns associated with ammonia. Advanced leak detection systems and robust construction materials minimize the risk of leaks, ensuring safe operation.

Applications in Data Centers and Industry

Kaltra’s expertise in designing and manufacturing cooling solutions extends to various applications, including data centers and industrial processes. Data centers, with their high density of electronic equipment, generate significant amounts of heat. Efficient cooling is essential to maintain optimal operating temperatures and prevent equipment failure.

Ammonia heat exchangers can be integrated into chiller systems and free cooling systems to provide reliable and energy-efficient cooling for data centers. The use of ammonia not only lowers energy costs but also reduces the environmental impact of these power-hungry facilities.

In industrial settings, where cooling is often a critical part of manufacturing processes, ammonia heat exchangers offer similar benefits. From food processing to chemical production, these exchangers can help improve efficiency, reduce energy consumption, and minimize environmental impact.

Kaltra’s Commitment to Innovation

Kaltra continues to innovate in the field of cooling solutions, focusing on developing and refining technologies that maximize energy efficiency and minimize environmental impact. The company’s range of chillers, free cooling systems, precision air conditioners, and microchannel heat exchangers reflects its dedication to providing sustainable and reliable cooling solutions for data centers and industry.

By embracing environmentally friendly refrigerants like ammonia and investing in advanced heat exchanger designs, Kaltra is helping businesses around the world achieve their sustainability goals while maintaining operational efficiency. And as the demand for cooling continues to grow, the importance of efficient and sustainable solutions like ammonia heat exchangers will only increase.

Are ammonia heat exchangers the future of cooling? The evidence strongly suggests they will play a crucial role in shaping a more sustainable and efficient future for the industry.